Finish Architectural Knowledge Base

5 Benefits of Bespoke Steel Fabrication for Unique Projects

Bespoke steel fabrication offers a wide range of benefits for unique projects, making it a preferred choice in various industries. From enhanced customisation to superior quality and durability, the advantages of this manufacturing process are undeniable.

But what exactly are these benefits, and how can they positively impact your project? In this article, we will explore five key advantages of bespoke steel fabrication that will pique your interest and provide valuable insights into the world of customised steel solutions.

So, if you're curious about how bespoke steel fabrication can elevate your project to new heights, keep reading to uncover the transformative power of this innovative manufacturing technique.

Why is Steel Fabrication Important?

Steel fabrication is crucial for its ability to tailor products to exact client specifications, offering unmatched strength, durability, and environmental benefits. It ensures a perfect fit and functionality, meeting specific client needs with precision.

Secondly, steel fabrication offers the benefits of strength, durability, and resistance to corrosion, making it a reliable choice for construction projects. Lastly, steel is a sustainable and recyclable material, contributing to environmental and social benefits in the construction industry.

What is Bespoke Steel Fabrication?

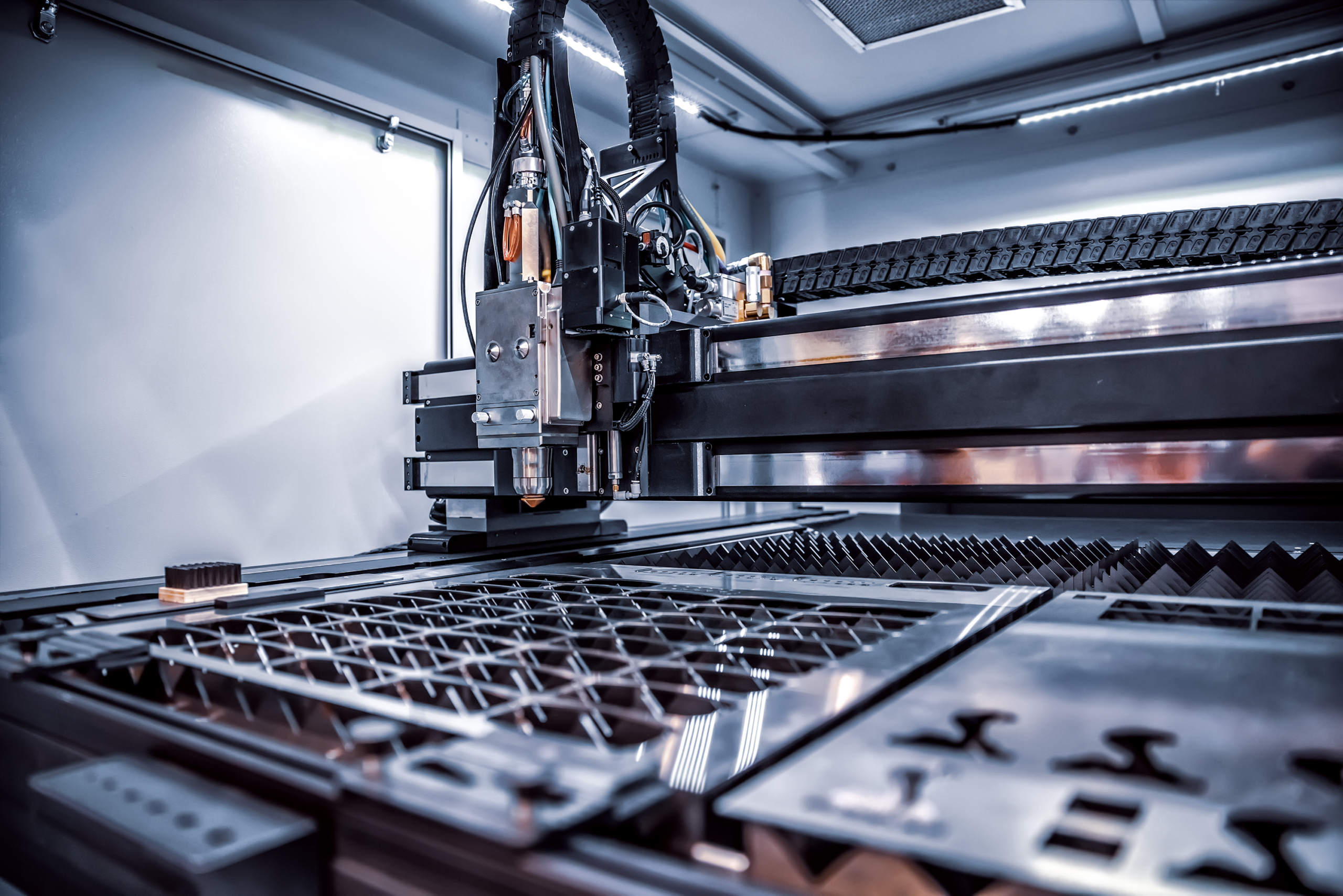

Bespoke fabrication is the process of custom-making metal products to specific client requirements. It involves shaping metal into unique, functional, or decorative items, tailored precisely to the desired dimensions and design.

Bespoke fabrication ensures precise results while streamlining production and minimising delays. This method aligns with just-in-time manufacturing, reducing the need for extensive storage. It enhances efficiency and control across industries, yielding high-quality, customised outcomes.

The Custom Fabrication Process Explained

The custom fabrication process, integral in meeting specific client needs and achieving high-quality, long-lasting solutions, plays a crucial role in various industries. Techniques like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding transform raw materials into functional components, adhering to exact specifications for high-quality metal parts.

Techniques such as cutting, bending, forging, casting, and machining are used to transform raw materials into functional components. Adhering to exact specifications and precise measurements ensures the production of high-quality metal parts. Custom fabrication services include cutting, bending, and welding to create unique, tailored products.

Benefits of Using Bespoke Steel Fabrication for Your Projects

Bespoke steel fabrication offers significant benefits, particularly in construction projects. It provides the flexibility of customisation and assures quality, tailored to meet specific requirements. In the following sections, we'll delve deeper into these advantages, showcasing how bespoke steel fabrication can be a viable solution for your project.

It Offers Solutions for Business Needs

Businesses can enhance their operations and meet specific requirements by utilising bespoke fabrication services for their metalwork projects, differentiating themselves with unique, customised products. For example, a bespoke staircase not only meets functional needs but also adds a distinct aesthetic appeal.

By choosing bespoke fabrication, businesses can offer their customers unique and customised products.

This allows them to provide optimum solutions to their customers, clients, and colleagues, increasing satisfaction levels. Moreover, businesses can ensure certain standards are met and be more efficient by having the exact bespoke fabrication requirements they need, rather than compromising with standard options.

It Ensures Superior Quality and Durability

Opting for bespoke fabrication services ensures superior quality and longevity in metalwork projects. Custom-made items, tailored to evolving industry standards, offer durability that prefabricated components often lack.

Custom metal fabrication focuses on creating well-designed products, precisely tailored to unique specifications, leading to more durable and long-lasting solutions. This approach not only reduces the likelihood of early replacements but also offers better long-term value for money.

It saves Time and Helps reduce costs

Custom fabrication brings significant time and cost benefits, stemming from its bespoke design and enduring durability. Despite a higher upfront cost, the long-term savings are substantial. Custom-made items often demand less maintenance and repair, thanks to their tailored design and robust construction.

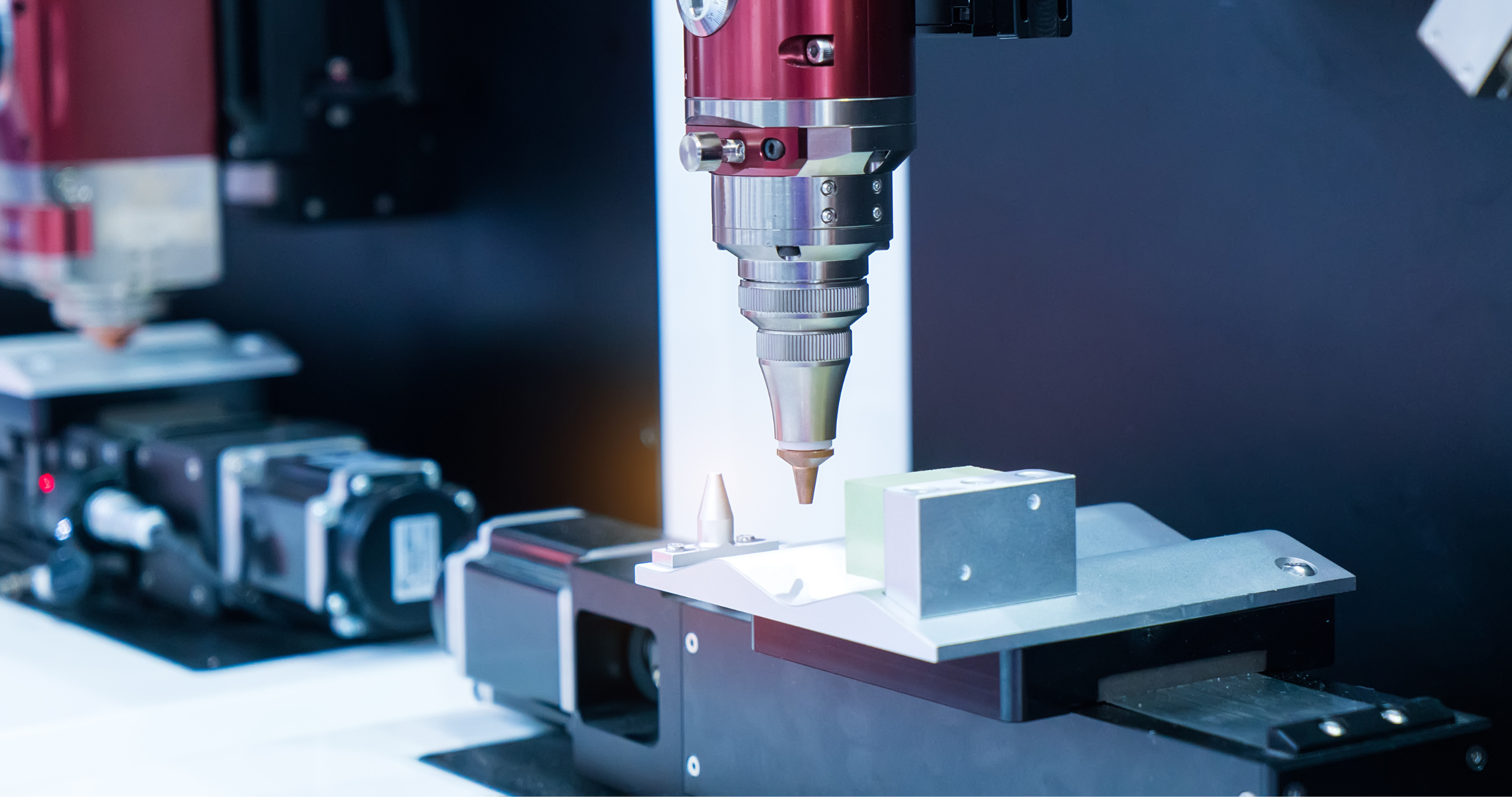

Advanced machinery, like CNC technology, used by skilled fabricators, enables quick and precise cuts and finishes. Moreover, employing a professional team to create metal works exactly to your specifications streamlines the process, saving time and resources from the outset.

It Delivers Precision and Compatibility

Bespoke fabrication excels in delivering precision and compatibility, crucial for projects demanding meticulous attention to detail. Custom steel fabrication, leveraging cutting-edge technology and machinery, offers a higher degree of precision compared to other methods.

Such precision is vital for complex structures or products where accuracy is paramount. Furthermore, custom metal sheet fabrication ensures seamless integration with existing systems, tailored to meet specific requirements and guarantees an exact fit for your project.

It Leverages Expert Craftsmanship

Custom metal fabrication is a highly specialised service, demanding exceptional skill and expertise. Choosing bespoke metalwork services grants you access to highly trained engineers and designers. These professionals are adept at creating quality products tailored to your specific requirements.

In addition to having a skilled workforce, opting for bespoke fabrication services ensures that your products are crafted using the latest techniques, methods, and technologies. This combination of expert personnel and advanced manufacturing processes guarantees that the end products are of exceptional quality, meeting and often exceeding your expectations.

Elevate Your Project with Finish Architectural's Bespoke Metal Fabrication Services

Are you in need of precision-crafted metalwork that stands the test of time?

Look no further than Finish Architectural's Bespoke Metal Fabrication Services. Our team of skilled craftsmen, equipped with state-of-the-art technology, is dedicated to transforming your vision into reality. From intricate architectural pressings to robust balcony frames, our bespoke solutions are tailored to meet the unique needs of your project.

Whether you're tackling a large-scale development or a smaller, specialised project, our versatile approach ensures precision, quality, and compatibility. With our expertise in working with a variety of materials like mild steel, stainless steel, and aluminium, we offer the adaptability to suit your specific requirements.

Don't compromise on quality. Choose Finish Architectural for bespoke metalwork that combines expert craftsmanship with cutting-edge techniques. Contact us today to bring your bespoke metal fabrication project to life

Need more information?

To see how Finish Architectural could support your next project - simply call us, or use the form below.