Finish Architectural Knowledge Base

Benefits of Powder Coating Aluminium

Are you wondering what the benefits of powder coating Aluminium are?

Firstly, powder coating elevates the durability, longevity, and aesthetic appeal of aluminium products. This protective coating shields against corrosion, wear, and environmental damage, making it a cost-effective choice for enhancing your items.

With minimal maintenance, powder-coated aluminium can withstand harsh conditions, ensuring that your aluminium products remain in pristine condition. Additionally, powder-coating aluminium unlocks the possibility of personalising aluminium products with a wide array of colours and finishes, tailoring the look to your specific needs.

Businesses in industries such as automotive, aerospace, and architecture already leverage these advantages for superior product protection and style.

So if you want to follow suit, keep reading this article to learn how powder coating can transform your aluminium products.

Advantages and Disadvantages of Powder Coating

Powder coating transforms aluminium products, boosting their performance and aesthetic appeal through several key benefits:

- Enhanced Durability and Resistance: Aluminium products gain an extra layer of protection, making them more resilient against scratches, impacts, and corrosion.

- Increased Longevity: This durable finish extends the life of aluminium items, ensuring they look and function well for years to come.

- Cost-Effectiveness: Powder coating is a smart financial choice, reducing the need for frequent maintenance or replacements.

- Environmental Advantages: It's a greener option, with processes that minimise harmful emissions and waste.

In the following sections, we'll delve deeper into each of these advantages, exploring how they contribute to the superior quality and sustainability of powder-coated aluminium products

Disadvantages of Powder Coating

Powder coating isn't without its challenges. The initial setup and equipment costs can be higher than traditional painting methods, making it less accessible for small-scale projects or individual users.

Additionally, colour matching and consistency can pose difficulties, especially for complex or custom hues. The process also requires a high level of expertise to ensure a uniform coat, and once cured, powder coatings are difficult to repair or touch up without redoing the entire piece.

Despite these considerations, the advantages of powder coating aluminium outweigh the disadvantages.

So, keep on reading to learn more and make an informed decision for your next project.

In-Depth Look at Powder Coating

Powder coating involves a polyester-based coating using accurately sized microbeads with an electrostatic charge that adheres to base materials. When heated, these microbeads form a hard coating that can be customised with various colours and finishes.

There are two forms of powder coating materials: Thermoplastics, known for their flexibility, durability, and impact resistance, and Thermosets, typically epoxy or polyurethane-based powders offering versatility but with less predictable results due to varying reactivity levels.

This process is essential in providing aluminium with advantages like corrosion and abrasion resistance, improved durability, and enhanced aesthetic appeal.

Why Choose Aluminium for Powder Coating?

Choosing aluminium for powder coating offers numerous benefits, making it a popular choice in various industries. Aluminium is favoured in the automotive and aerospace sectors for its lightweight yet strong characteristics. However, it is prone to rust and corrosion without proper treatment.

Powder coating provides a protective barrier against these elements, as well as wear and tear, extending the lifespan of the material with minimal maintenance requirements.

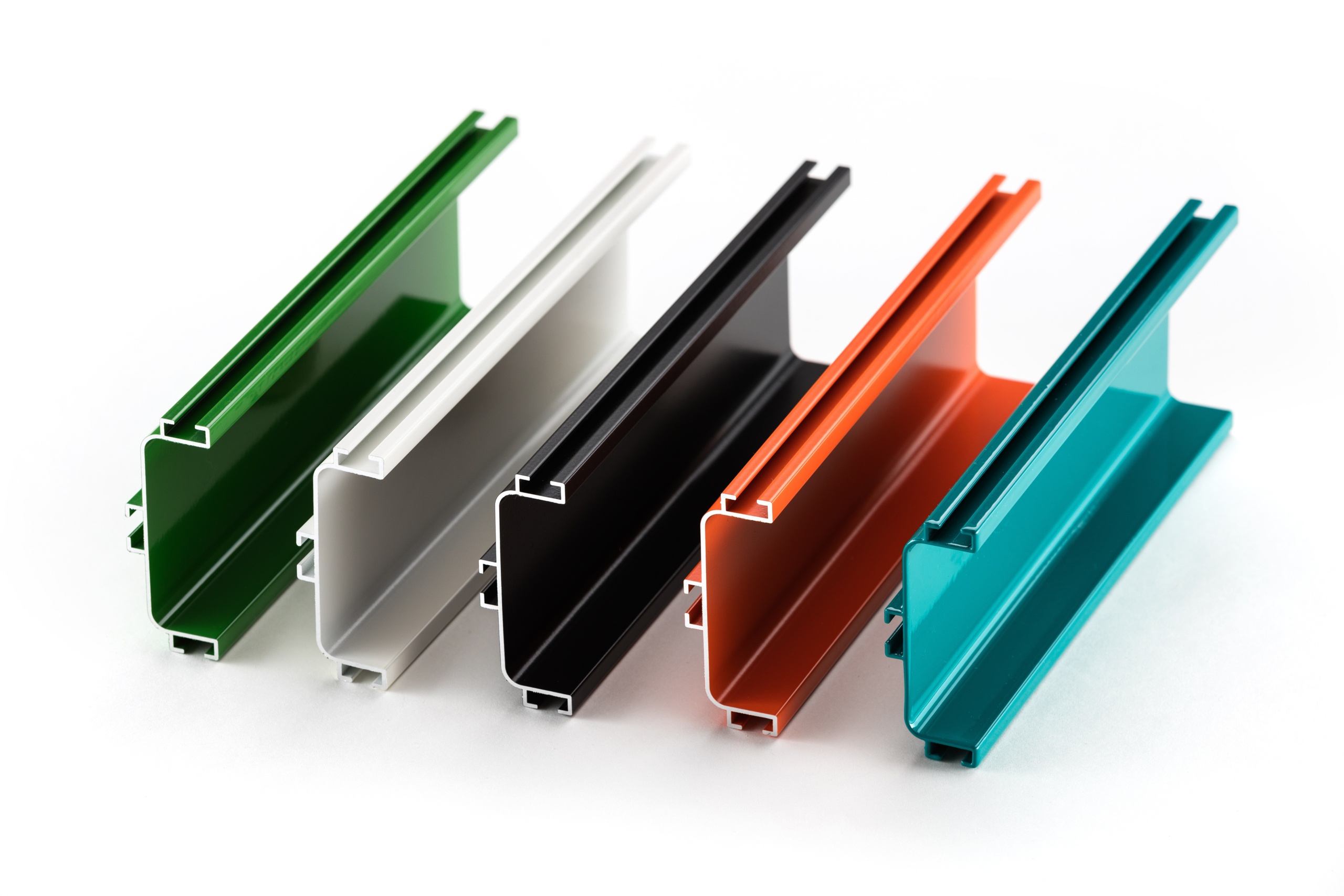

Additionally, powder coating enhances the finish of aluminium, offering a wider range of colours and finishes compared to traditional paint. These coatings are more resistant to fading and chipping, providing a durable and aesthetically pleasing solution for protecting and enhancing aluminium surfaces in different applications.

The Benefits of Powder Coating Aluminium

Now, let’s discuss the benefits of powder-coating aluminium.

1. Enhanced Durability and Resistance

Improving durability and resistance, powder coating aluminium offers a strong protective layer against corrosion and wear, ensuring longevity and minimal maintenance. This process involves applying a polyester-based coating with electrostatically charged microbeads that adhere to the aluminium surface. Once heated, these microbeads form a hard coating that shields the aluminium from environmental elements.

By opting for powder coating, you greatly enhance the lifespan of your aluminium products, reducing the need for frequent upkeep. This heightened durability means your aluminium items can withstand harsh conditions and daily use without deteriorating quickly. Overall, powder coating provides a dependable solution to safeguard your aluminium investments for years to come.

2. Increased Longevity

Another benefit of powder coating aluminium is that it increases the longevity of aluminium products.

By providing a durable protective layer against corrosion and wear, powder coating acts as a shield, safeguarding elements like moisture and UV rays from causing damage to the metal surface.

By forming a tough barrier, powder coating guarantees that your aluminium products can withstand harsh environmental conditions and everyday use without deteriorating quickly. This means that your items will maintain their appearance and structural integrity for a longer period, reducing the frequency of repairs or replacements.

Powder coating not only enhances the durability of your aluminium products but also minimises the need for extensive maintenance, saving you time and money in the long run.

3. Cost-Effectiveness

Alongside increasing the longevity of aluminium products, powder-coating is also a cost-effective solution for preserving the material's integrity and appearance over time.

Powder coating can save you money in the long run as the durable finish provided by powder coating reduces the need for frequent repainting or touch-ups, reducing maintenance costs.

Additionally, powder coating is a more efficient process compared to traditional painting methods, saving you time and labour expenses.

4. Environmental Advantages

When considering the benefits of powder coating aluminium, you cannot overlook the significant environmental advantages this offers. Powder-coated materials are more attractive, durable and provide better protection than traditional paint methods.

What sets it apart is its eco-friendly nature, as it is free from Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs), emitting virtually no air pollution even during high-volume orders.

Practical Applications of Powder-Coated Aluminium

Practical applications of powder-coated aluminium extend across various industries, showcasing its versatility and durability. In architectural structures, powder-coated aluminium is favoured for its corrosion resistance and aesthetic appeal, making it a popular choice for windows, doors, and facades.

The automotive industry utilises powder-coated aluminium for lightweight components that require durability against harsh conditions.

Outdoor furniture and equipment benefit from the weather-resistant properties of powder-coated aluminium, ensuring longevity and minimal maintenance. In electronics and consumer goods, the even finish and colour options of powder-coated aluminium enhance product aesthetics and protect from wear and tear. These diverse applications highlight the practical advantages of using powder-coated aluminium in various settings.

Choosing the Right Powder Coating Service

Selecting the optimal powder coating service provider for your project necessitates careful consideration of their expertise and quality assurance measures. Before finalising a choice, confirm that powder coating is appropriate for your specific project and that the company offers surface preparation if needed. Seek out contractors who exhibit their work through an online gallery, showcasing a variety of completed projects.

Validate if the company has a strong quality control and assurance strategy in place, including auditing processes and stress testing of powder-coated panels. Professionalism indicators like transparency in sharing stress test results and a proven track record of quality services are vital.

Ultimately, you should opt for a powder coating service that inspires confidence in the protective layer they provide and guarantees the best possible outcome for your project's surface.

Elevate Your Projects with Finish Architectural

Choose Finish Architectural for top-tier bespoke aluminium fabrication. Our expertise ensures your projects are not just visually stunning but durable and eco-friendly. Ready to transform your ideas into reality?

Contact us today and let's create something extraordinary together.

Need more information?

To see how Finish Architectural could support your next project - simply call us, or use the form below.