Finish Architectural Knowledge Base

A Guide to Anodised Aluminium Colours: What Options are Available?

From corrosion resistance to durability, anodised aluminium comes with a variety of benefits, but it is also essential to understand the variety of colour options available through different anodising processes. You'll find that factors like the anodising method and colour matching can significantly influence the final outcome.

Looking for an Anodising Aluminium Service?

At Finish Architectural, we provide a range of metal finishing services, including anosiding aluminium services. It can be used for a variety of industries including residential, industrial and commercial.

Reach out to us here for prices and information.

What is Anodised Aluminium?

Anodised aluminium is a metal that's undergone an electrolytic process, resulting in a durable and corrosion-resistant oxide layer. This process involves immersing the aluminium in an electrolyte bath while applying an electric current.

As positive ions exit the metal, negative O2 ions bond to create a robust oxide surface. This anodised finish provides integrated corrosion protection, making it ideal for outdoor applications without the risk of peeling or chipping. The enhanced durability in harsh environments ensures it's suitable for both indoor and outdoor furnishings.

There are many worthwhile benefits of anodised aluminium products, as they require minimal maintenance, offering high impact resistance.

Colouring Anodised Aluminium: How is it Done?

When you're looking to add colour to anodised aluminium, several acid-based processes come into play.

Sulphuric, chromic, and oxalic acid anodising each offer unique characteristics, while hard anodising provides an exceptionally durable finish, and understanding these methods will help you select the best option for your project's aesthetic and functional needs.

Sulphuric Acid Anodising

One effective method for colouring anodised aluminium is through sulphuric acid anodising, a process that not only enhances the surface but also embeds colour into the oxide layer. During the process, the oxidation creates a thick, porous oxide layer, which can absorb dye.

You can choose from a wide palette of colours, ranging from standard finishes like Natural Silver and Black to specialised hues. After dyeing, a sealing process is employed to close the pores, ensuring colour permanence and durability. This method not only improves aesthetics but also maintains the protective qualities of anodised aluminium, making it ideal for various applications.

Chromic Acid Anodising

Utilising chromic acid anodising presents a unique method for colouring anodised aluminium, offering distinct advantages in both performance and aesthetic appeal. This process involves immersing aluminium in a chromic acid electrolyte bath while applying electrical current, creating a dense, protective oxide layer. The resulting finish not only enhances corrosion resistance but also allows for dye absorption, resulting in vibrant, durable colours.

With chromic acid anodising, you can achieve a smoother surface, ideal for high-quality finishes. The colours developed through this technique retain their integrity over time, making it perfect for applications requiring long-lasting visual impact.

Oxalic Acid Anodising

Oxalic acid anodising offers another effective method for colouring anodised aluminium, distinct from chromic acid anodising. In this process, aluminium is immersed in an electrolyte solution of oxalic acid, creating a thick, porous anodic layer. This layer allows for the infusion of dyes, enabling a wide range of vibrant colours.

The dyeing process enhances durability and resistance to fading. You'll find that oxalic acid anodising is particularly suited for architectural applications, where aesthetics and longevity are crucial.

Hard Anodising (Hardcoat Anodising)

Hard anodising, often referred to as hardcoat anodising, is a specialised process that consistently enhances the durability and wear resistance of aluminium. This method involves immersing aluminium in an electrolytic bath, where an electric current triggers the oxidation process, forming a thick, dense oxide layer.

Unlike conventional anodising, hard anodising creates a harder surface that significantly improves abrasion and corrosion resistance. The thickness of this oxide layer can be tailored to meet specific application requirements, making it ideal for demanding environments.

Colour Matching in Aluminium Anodising

Achieving accurate colour matching in aluminium anodising is crucial for ensuring aesthetic consistency across projects.

You'll want to start by selecting the right anodising process and colourants, as these significantly affect the final hue. It's essential to use standardised colour samples for reference during production to mitigate variations. Additionally, maintain uniformity in your aluminium substrates by ensuring they're cleaned and prepped uniformly. Factors like surface finish and thickness can influence colour appearance, so consider these elements in your design.

Regularly test batches during production to confirm that colours align with your specifications. By meticulously managing these variables, you can achieve precise colour matching that enhances the visual impact of your anodised aluminium pieces. It is worth noting that a 100% match cannot be guaranteed due to the difficulties of a complete match in shade, type of dye, and the variation in aluminium used. However, achieving a colour match isn't impossible, just ensure you have a good sample.

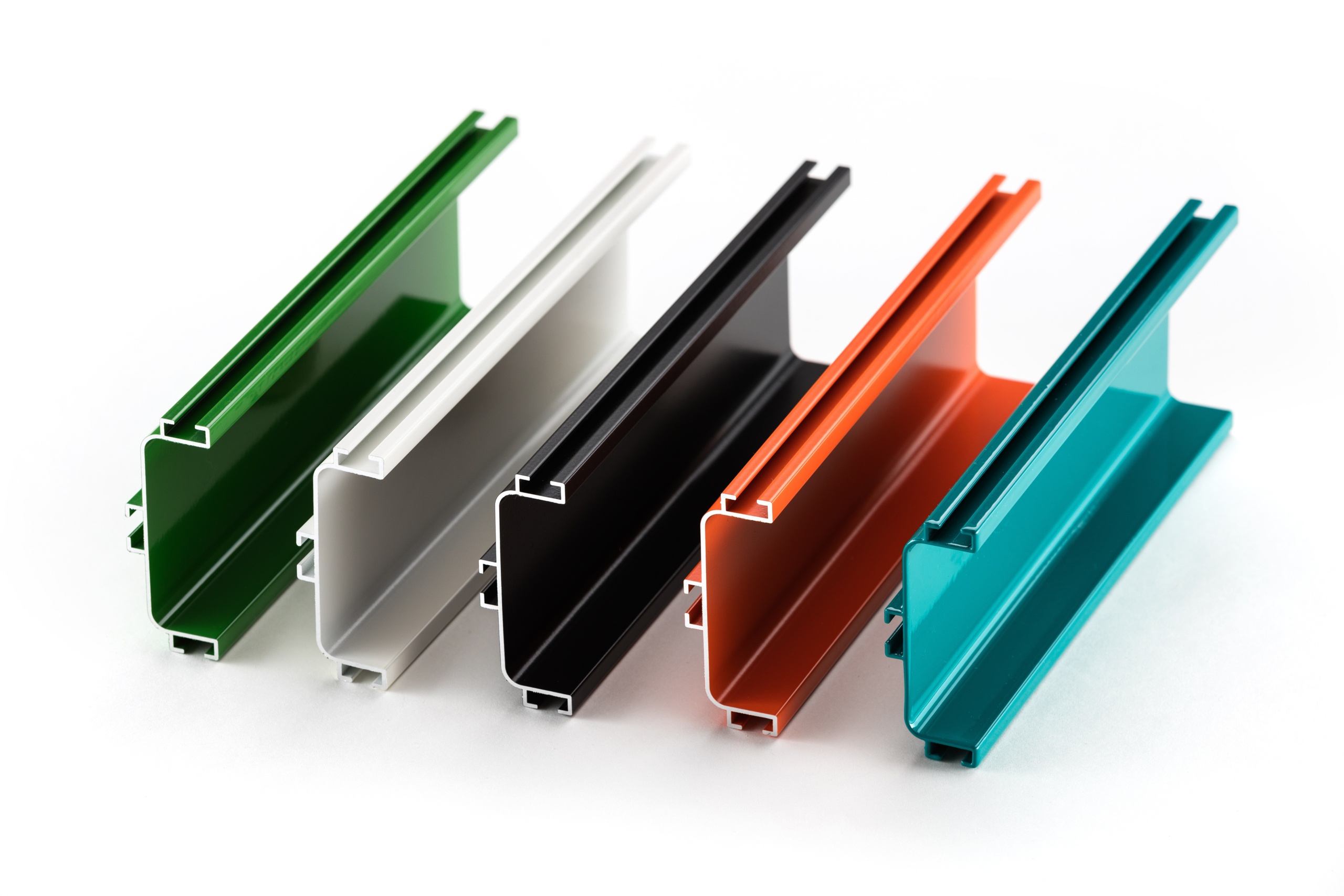

What Colours Can Be Aluminium Anodised?

When considering aluminium anodising, you'll find a diverse palette of colours available to enhance both functionality and aesthetic appeal.

Standard colours include Natural Silver, Bronzes, Regency Gold, and Black, which provide a classic look while maintaining durability. If you're after something more unique, specialist finishes like Anolok II Blue-Grey and Stone-Grey offer a refined touch that can set your project apart.

Considerations for Anodising Colour Matching

When you're matching anodised aluminium colours, compliance with industry standards is crucial for consistency and quality. You must also prioritise surface preparation, as it significantly influences the final appearance and adhesion of the dye. Additionally, consider various dye selection factors, as they can impact both the vibrancy and durability of the anodised finish.

Industry Standards Compliance

Colour matching in anodising isn't just a cosmetic consideration; it's a critical aspect that ensures compliance with industry standards and client expectations.

Achieving precise colour matching demands rigorous adherence to established protocols, including ISO standards, which dictate the quality of anodised finishes. You'll need to ensure that the colour consistency aligns with your project's specifications, as even minor deviations can lead to significant issues in aesthetics and client satisfaction.

Regular testing and calibration of anodising equipment are essential to maintain this compliance. Additionally, documentation of the anodising process, including colour samples and batch records, provides traceability and assures clients that you're upholding industry standards.

Surface Preparation Importance

Surface preparation plays a crucial role in achieving consistent and high-quality anodised finishes.

Before anodising, ensure the aluminium surface is thoroughly cleaned and free of contaminants like oils, dirt, and oxidation. This step is critical, as any residual material can lead to uneven colour distribution and compromised adhesion of the anodised layer.

Utilise appropriate chemical cleaners or mechanical methods to treat the surface, depending on the condition of the aluminium. Additionally, consider the texture of the surface; smoother finishes typically yield more uniform colour outcomes.

Dye Selection Factors

Choosing the right dye for anodising is crucial for achieving the desired aesthetic and performance outcomes.

When selecting a dye, consider the compatibility with the anodising process and the specific aluminium alloy you're working with. Different dyes react uniquely based on the alloy's composition, which can affect the final colour quality and durability.

Also, evaluate the lightfastness and resistance to fading, especially for outdoor applications. Pay attention to the dye concentration; higher concentrations can lead to richer colours but may also affect the uniformity of the finish.

Finally, factor in your project's environmental conditions, as exposure to elements can influence colour retention.

How We Can Help

If you're looking for expert architectural services that blend innovation with functionality, look no further than Finish Architectural. Our team of skilled professionals is dedicated to bringing your vision to life, ensuring that every project reflects your unique style and meets your needs.

With a strong commitment to quality and attention to detail, we are here to guide you through every step of the design process.

Need more information?

To see how Finish Architectural could support your next project - simply call us, or use the form below.